The SMART URBAN CONTINUUM moves away from the traditional linear "take-make-dispose" model towards a closed-loop system where materials are kept in use for as long as possible through the implementation of ZERO WASTE technologies.

The more Smart innovations employed, the more efficient a city becomes. IE: The further along the continuum the more efficient a city becomes.

This approach not only reduces environmental impact but enhances efficiency, safety and financial sustainability of maintenance operations.

"Business as Usual" Is No Longer an Option

Cities using traditional reactive maintenance methods remain in a constant state of decay, each eyar growing more costly adn difficult to maintain.

In stark contrast a city employing ZERO WASTE and SMART technologies grows increasingly efficient and sustainable

Advanced Polymer resilient bollards and bollard covers. Safer, more resilient bollards

Saving old solar panels from landfill and lighting up your city

AI sensors for detecting damage

Identifying damaged infrastructure can now be greatly simplified by the integration of SMART SENSORS that alert authorities the moment of impact.

A simple solution that unlike other systems- does NOT cost the earth.

By coupling this technology with ZERO WASTE Foundations you can replace damaged items within moments of the damage

Growing risk of litigation

Delays in replacing damaged road signs could potentially lead to legal action if these delays cause an accident or injury, and the injured party can prove the responsible authority failed to act with reasonable care.

Roadworks often lead to increased traffic congestion and potential delays due to lane closures, detours, and reduced speed limits. These disruptions can cause frustration for drivers and impact travel times, especially during peak hours. There is a growing need to mitigate these issues.

Once notified of damage it can take weeeks before a sign is replaced. In some cases, weather conditions can impact repair timelines and heavy traffic can also be cause for delays.

For example, heavy rain or extreme temperatures might make it unsafe or impractical to carry out certain repair using traditional methods.

In addition to this, replacing the foundations requires "dial before you dig" - (or click before you dig) , safety reports, traffic management plans and set up, traffic management planning and hours of digging and heavy labour - often in dangerous environments.

Simply by installing ZERO WASTE Foundations you can replace damaged infrastructure in literally seconds (no matter what the weather) eradicating delays and the risk of litigation.

Fast replacements are critical

A damaged or missing STOP sign or traffic light can be fatal- now that a simple low cost solution is available it is not just smart, but you have a legal obligation to reduce risk to both the public and your workers.

We can help make your life easier, substantially improving efficiency and reducing risk

Alarming Trends for road authorities

In the UK, frontline road workers are now required to undergo self-defence training, as abuse and assaults rise dramatically on public works crews. In the USA, silicosis claims are skyrocketing, with compensation reaching into the hundreds of millions annually, forcing departments to rethink traditional concrete removal practices.

National Infrastructure Burden (2024):

-

Over $1.2 billion lost annually due to utility strikes and reworks.

-

Workplace injuries in roadworks costing over $640 million per year.

-

Waste management costs are rising 12% annually.

-

Millions in fines and investigations related to poor WHS and EPA compliance.

-

Obligation: Under the Model WHS Act, authorities must ensure the health and safety of all workers.

-

Reality: Traditional methods put workers at risk of body stressing (The number one cause of injury)

-

Reality: Traditional methods put workers at risk of injury spending hours every day working in dangerous traffic (the number one cause of serious workplace injury)

-

Reality: Traditional methods put workers at risk of serious or fatal injury from disturbance to (often poorly marked) dangerous underground services

-

Reality: Traditional concrete installations put workers at risk of silica exposure, with projections suggesting payouts will cost road authorities (esp maintenace sector) millions in the coming years

One serious WHS breach can incur penalties of up to $3.5 million for corporations.

WHS Obligations are mounting

A sign of what's coming:

HSE Fines Surge: UK courts handed out over £35.8 million in health and safety fines in 2023 alone — a 44% increase from the previous year.

HSE random inspections now impact 1 in 5 local road projects

Environmental and waste regulations

Failure to comply with the UK Environment Agency’s waste tracking and disposal regulations can result in fines up to £500,000 and criminal prosecution.

In the USA, the EPA has increased federal fines of up to US$50,000 per day for improper disposal

-

Obligation: The EPA mandates all waste be managed under licensed transport and disposal schemes.

-

Reality: 100% of the concrete and paving used to secure roadside items goes to landfill

-

Reality: Breaking up concrete footings creates waste that requires licensed removal and tipping—costly and time-consuming.

Cost: Landfill levies and tipping fees vary by state but are rising rapidly—up to $250/tonne in some regions.

-

Obligation: Councils and State Road authorities must demonstrate they’ve considered whole-of-life cost, environmental impact, and social outcomes.

-

Reality: Failing to procure sustainable products and implement sustainable practices can result in failed audits, public criticism, and result in spiraling costs

Best-Practice Procurement Standards

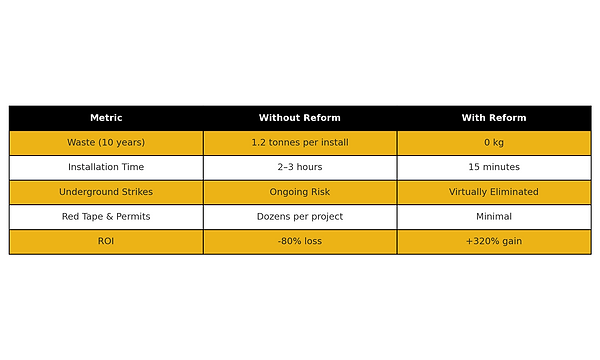

Key Efficiency Gains

-

Substantial reduction in worker exposure to high-risk tasks

-

Elimination of waste transport and disposal obligations

-

Minimal traffic management costs

-

Dramatically reduced paperwork and approval delays

Reality: You can reduce your costs and risks by around 80% within 2-3 years.

If changes aren’t made soon, road authorities will face growing exposure to litigation—from injured workers, environmental regulators, and auditors—each with the power to shut projects down or issue crushing penalties.

Expect more:

-

Blowouts

-

Injuries

-

Fines

-

Public scrutiny

-

Burnout

This is a warning. Not a sales pitch.

The system is failing—but there is a better way.

What’s at Stake?

Inaction at this stage could render your organisation or department operationally and financially untenable within a few short years

Let's build a better future

There's good reason the major road developers, Western Power, Department of Transport, and Australia's major Local Government authorities buy our products- it is because our products reduce waste and consumption, improve safety and efficiency and save you money, a LOT of money.

100 %

No replacing valuable footings. Replace damaged items in seconds- no heavy labour for 100 years

Click on arrow and please wait for video to load

With rapid urbanisation and climate change the road construction and particularly the road maintenance sector is undergoing major challenges

This, already difficult work, is about to become more difficult to perform and with rising damage budgets will become even more difficult to manage.

It’s time to take this ridiculously complex job and make it crazy simple

"Our selection is not based on price alone, we also took into consideration the safety and saving aspects. ZERO WASTE Unbreakable Foundations allow quick replacement of items with no further effort required to the base, (providing a significant cost benefit in replacing the damaged item by re-using the existing footing) and reduces risk of injury to employees by reducing time spent on traffic islands exposed to traffic.”

MAIN ROADS DEPT W.A.